APPLICATIONS OF REGENERATE RUBBER IN PRODUCTION

Today, regenerated rubber is divided into many types based on the input materials used for recycling such as SBR regenerated rubber, EPDM regenerated rubber, and NR regenerated rubber, ... This type of material is widely used in many countries.

High flexibility regenerated rubber can increase the mixability between primary rubber and additives. This helps regenerated rubber can completely or partially replace primary rubber for use. In addition, the cost of regenerated rubber compared to primary rubber is relatively cheap, so it becomes an important raw material in the rubber industry.

The use of regenerated rubber accounts for up to 50%, and some low-end products can completely use regenerated rubber. This can greatly reduce the cost of rubber products.

Some popular products use recycled rubber in products such as tires, shoe soles, rubber hoses, conveyor belts, construction rubber, etc.

- Rubber tires: Tires such as truck tires, industrial tires, agricultural tires, or off-road tires, whose primary raw material is rubber and use a part of regenerated rubber in the production process. The mixing of regenerated rubber in the manufacturing process can increase the mechanical properties and improve the performance of the tire. At the same time, this formula also reduces the cost of rubber raw materials, achieving great economic and social benefits

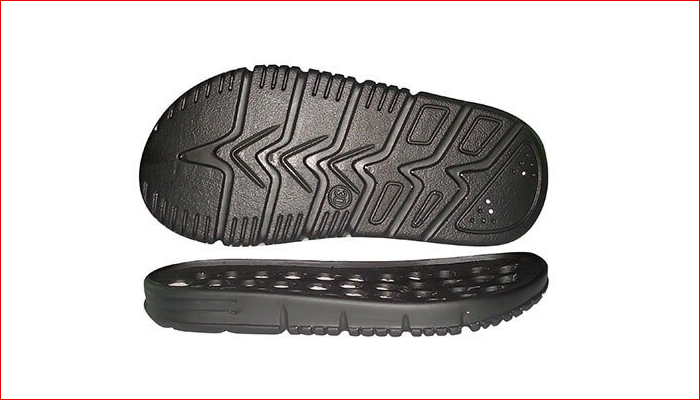

- Rubber soles using regenerated rubber are easily mixed with other materials and chemical components, helping to reduce power consumption, and adapting to different products. However, because this is a recycled product, the elasticity, crack resistance and tear resistance cannot be restored to the original level. When comparing some properties of neoprene with a part of regenerated rubber, with the exception of the reduced tensile strength, most of the other indices are in the standard.

- Rubber hose: Rubber hose is composed of inner layer material, outer layer, and frame layer. The requirements for the mechanical properties of the pipe are low. Mainly it is used in static mode, so a large amount of regenerated rubber can be mixed into the product. The inner layer regenerated rubber accounts for more than 80%. The outer shell rubber needs better aging resistance, so regeneration is only about 30%~50%.

Regenerated rubber is applied in many industrial rubber products, depending on the specific product, the manufacturer will mix in different percentages to ensure the product has a suitable price while still providing the product quality.

Mega Vietnam General Business Co., Ltd. has been widely deployed in the rubber market with many regenerated rubber codes such as MG1, MG7, EPDM, NBR regenerated, regenerated Latex, etc. With quality, The quality and design are diverse in terms of customer requirements as well as origin. With experience in the field of rubber and plastic, Mega is always a reliable partner and accompanies you to success.

>> Click HERE for the best paint chemicals on the market<<

Contact

MEGA VIETNAM

Office address: Floor 2-A2-IA20, Nam Thang Long Urban Area, Pham Van Dong Street,

Dong Ngac Ward, Bac Tu Liem District, Hanoi City, Vietnam

Email: contact@megavietnam.vn

Tel: (+84) 24 375 89089; Fax: (+84) 24 375 89 098

Website: megavietnam.vn

Hotline: 1800.577.728 Zalo: 0971.023.523